So you want to start reloading ?

OK, first question is why ? Not being rude but the answer to that can be very telling as to your projected success in the task.

To save money due to the increasing cost of commercial ammo ? That does not happen with most successful reloaders. You will end up shooting more, ergo just shooting up the cost savings.

To be able to shoot when commercial ammo is scarce like it is now ? That is a better reason since it is more realistic.

Whatever the reason, reloading is a hobby in its own right. That is a good thing. It is also very repetitive, and can be considered dull and boring, but with a serious twist. The level of attention required, even on dull repetitive tasks, is hard to maintain but loss of that attention or generic distractions from those tasks can get you into trouble very fast. I like to compare it to driving a car, except there is no license needed for reloading. Long trips can be boring but loss of attention from fatigue or whatever can be all it takes to become a statistic. Likewise, there are all kinds of drivers out there, good and bad. Probably not what you want to hear but the parallel is very accurate.

Still want to go there ? OK, lets get started. Read. Then read some more. The ABC’s of reloading is a good primer. There are many others. The recipe books are also good. A recipe is a safe load parameter for a given caliber. The one I like best is the Lyman 49th Reloading Handbook. They do not cover a lot of gun powders, but they do cover both Lead and copper jacketed loads, and since they are a ballistics laboratory, they have pressure data as well. Most powder manufacturers also provide recipes on their websites.

Next is what ? You will probably be thinking about a Reloading Press. Not yet. Reloading has a strange division of labor. In my opinion, most of the labor is up front, getting cases prepared for final assembly. Most of the cost is on the tail end, getting the prepared cases assembled with powder and bullets, which is not very time consuming. Every forum I visit has the same story in reloading. What kind of Press do I need ? Then they run out and buy whatever had the most recommendations. Then the real questions begin, and NO RELOADING happens for a very long time. It don’t matter what they bought, they cannot use the press at all until they have cases properly prepared for loading. Some will bypass that by buying virgin brass so they can get started. Oopps. I can’t get the primers installed correctly. How do you do that ? The books say install primers 0.002 – 0.004 inches below the base. Mine stick out no matter what I do. Is that bad ? And it gets worse from there.

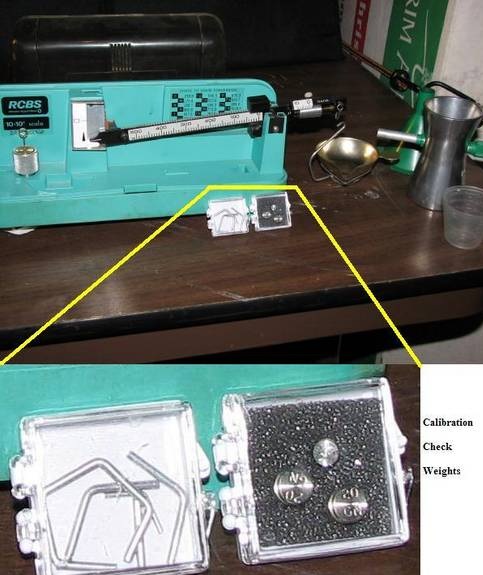

The books will tell you the general procedures and a good idea of what is required to produce good ammo. What they will not tell you is how to handle each step when you have a problem, because they cannot predict what you will encounter. Reloading requires that you manufacture something in your home, garage, etc., accurate to thousandths of an inch, and weights accurate to a tenth of a grain. There are 7000 grains in a pound, and 4,375 tenths of a grain in an ounce. It will amaze you at how creative people can be with problems when they start trying for laboratory accuracies in their garage. Especially when most of them have never been around a laboratory. Lets compound the situation by turning these folks loose with class A and B explosives.

This is where safety takes on a new meaning. I reload for myself, so I want to be absolutely anal retentive about safety. Meticulous, always looking for safer ways to do things. So much so that I almost do not trust factory ammo any more. I know a few reloaders that I trust and will shoot their ammo, because I have reloaded with them and I know them to be every bit as concerned about loading safety as I am. I know a lot more whose ammo I would not shoot on a dare.

Still want to dive in ? I will recommend an approach that few will ever take, because it makes sense. After the reading is done, start on the case preparation area. If possible, find an experienced reloader to work with. Acquire some basic case preparation equipment and use those first cases with the experienced reloader’s equipment to go through the loading steps. Get hands on exposure to the process and get by shooting your first loads. You will see how the process works for another loader and can better make adjustments for how you would like to do it. You will have experience with at least one type of loading press and be amazed at how you now have a feel for what is available and which equipment may better work for your own personal approach.

What I recommended above is what I am sorta doing now with one of my shooting buddies. He works full time and don’t have a lot of free time. My incentive for this is that I am playing with the idea of writing a book on reloading to address these uglier issues and need some hands-on experience with whether or not I can teach this stuff safely. Where we are at now is that when he gets a couple of hours or so free, usually either on a Saturday or Sunday afternoon, we get together to put together some .223’s, especially since you can’t find 223 anywhere now. Our next session will probably be this coming weekend, when we will load up a couple hundred or so 223’s. Following the 223, I can set up for a caliber of choice and away we go. I will not load for 357 Sig or 30 Mauser even if I had the dies since I believe these two pistol calibers are borderline safe even in factory loads. For pistols, I can set up for 380 auto, 9mm, 38 special, 357 Magnum, 44 special, 44 magnum, 45 auto, and 45 colt. I will probably add the .40 cal in the future simply due to popularity, even though I hesitate due to the cartridge design.

For those new to reloading, I recommend starting with a pistol cartridge for simplicity, and a revolver cartridge is the simplest of all. Rifles are a complication level above pistols and are best handled after you have some success with pistols behind you. But it never hurts to sit in on the process for rifles if the opportunity is there.

If this sounds like something you want to do, it is never too soon to start. Don’t run out and buy anything, well, except for a good reloading manual. Be ready to ask questions, and put to work doing mundane, repetitive tasks with…..explosives. But first, repetitive and mundane things like cleaning cases, reaming primer pockets, trimming cases, chamfering cases, etc. Note that doing these things for the most part does not require excessive investment, and if it drives you bonkers, you have not invested in a loading press and all the accessories there. You can still go back to factory ammo and have not spent a small fortune.