Paranoid about powder

This is one of those steps in reloading where it is easy to become paranoid, and if you are, then use the paranoia to focus on safety.

If I were an ammo factory, I would be in a statistically risky business which would demand that I take a statistically altered (very expensive) approach to quality checks throughout the production

process. I do not have that kind of investment capital, but since I am producing ammo for myself, I have a strong motivation to do everything I can to reduce the possible hazards to myself to zero.

I do have an advantage over an ammo factory in that my own time is available to add in exchange for lacking capital to buy all kinds of sensors for QC checks. Hopefully, I can show you how that

works, and use my approach or not, the added safety factors are there.

PROBLEM: I am so paranoid about squib and overcharge loads that I am willing to devote as much additional time to the reloading process as necessary to reduce the probability of such an event occurring at my reloading bench to zero (the goal). To do this, I continue to research the sources of errors in reloading with respect to squibs and overcharges. I believe the primary source to be a combination of the use of powder dispensers and inattention or distraction during the charging process.

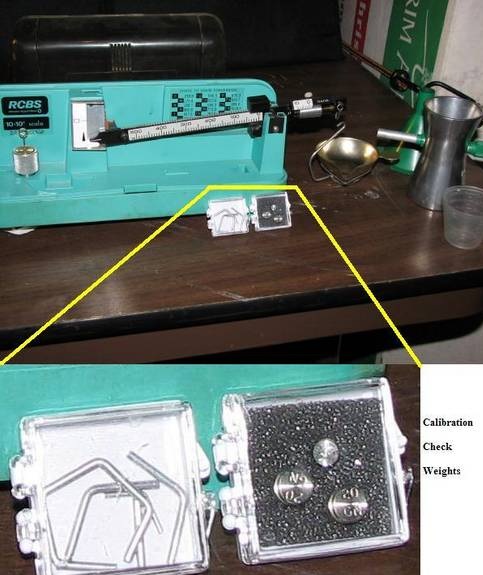

SOLUTION: What I have reached is an elimination of the powder dispenser as a means of dumping powder. Since I have a Dillon Progressive, the powder station is still there but kept empty and sealed, since I use that station for case mouth expansion ONLY. After case mouth expansion, I remove all cases (usually in lots of 50 at a time) to a separate bench where I manually dispense powder into the weigh scale one case at a time. Every case is hand-weighed and hand filled. After this, each lot of cases are positioned for inspection and all 50 cases have to look like clones of each other. When these cases come back to the loading bench, each case is examined again before placing the bullet and entering the bullet seating station. As to the weigh scale, it is calibrated before and after each 50 cases by using a mix of precision weights that EXACTLY equals the powder charge weight desired. To illustrate this, in the picture below, I show my scale along with a blowup of the precision weight set for calibration. This whole process adds about 20 minutes of time to the powder charge step (for each lot of 50 rounds), which I consider to be my own version of the equivalent of factory quality check sensors.